Design. Build. Deliver.

DESIGN.

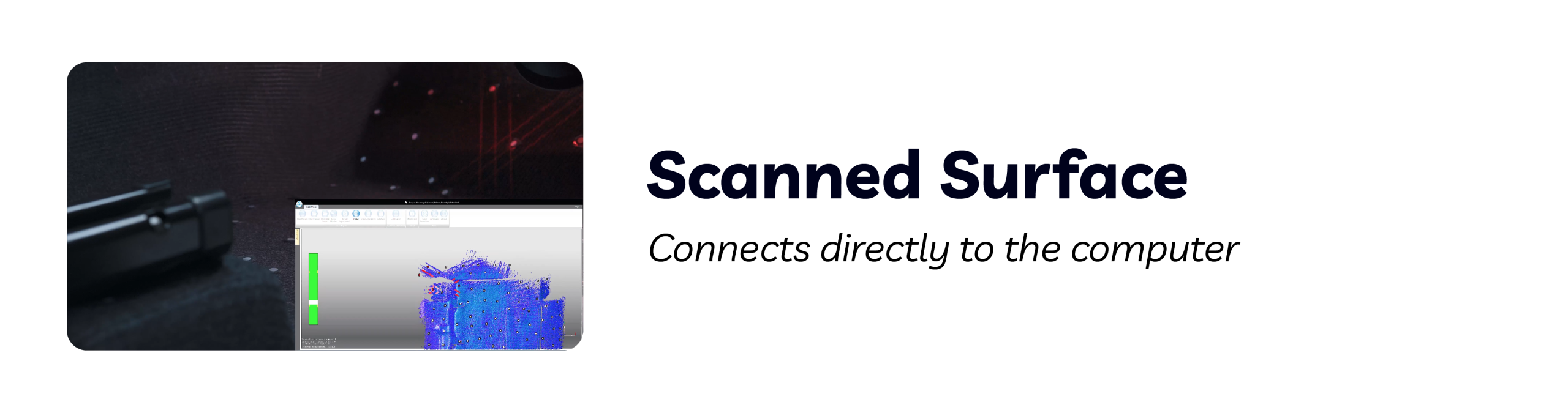

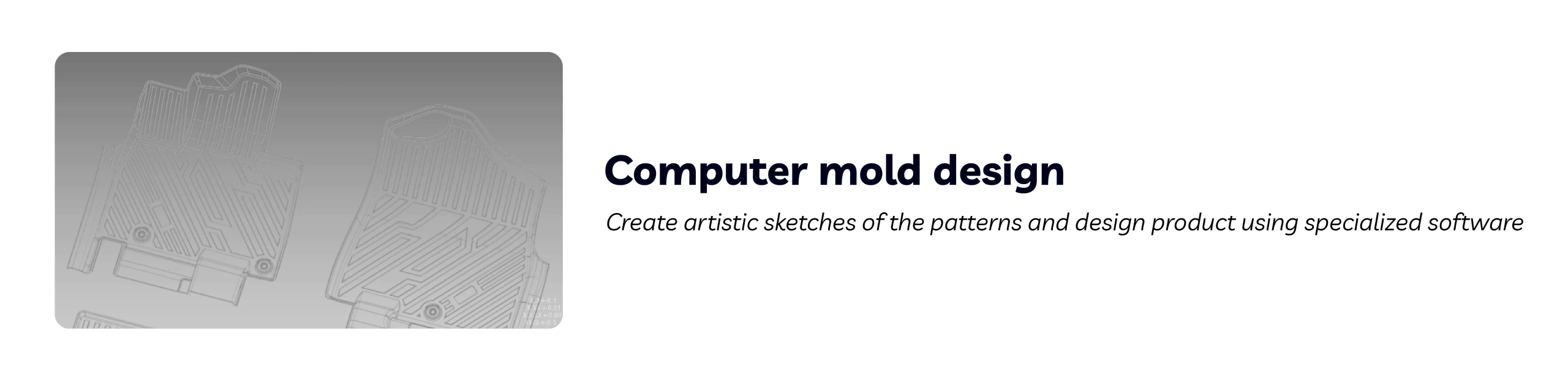

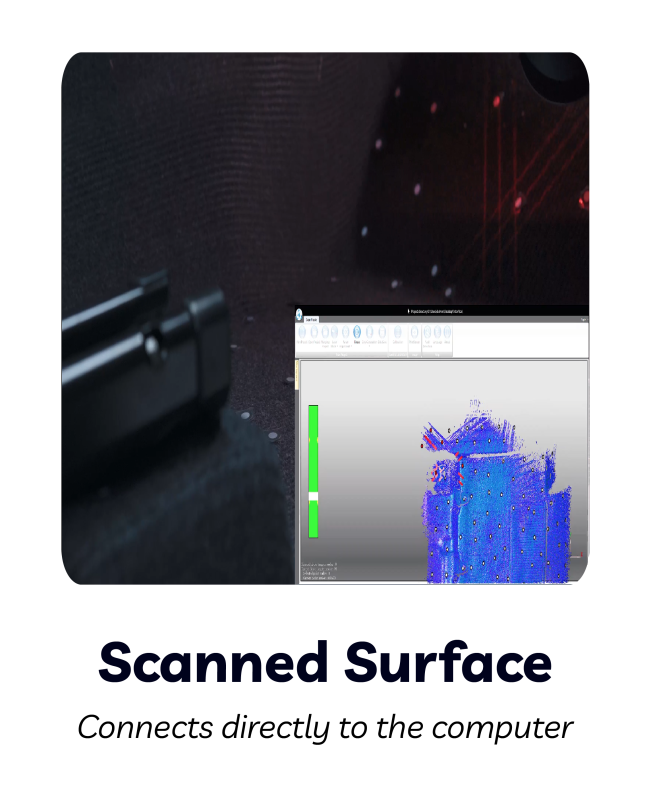

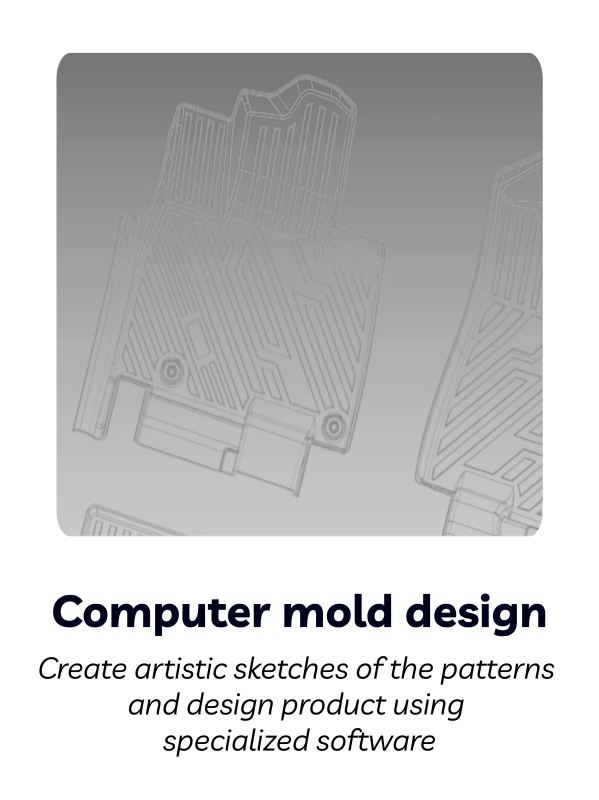

The machine uses a laser beam to scan the car floor, with a camera capturing the surface to reconstruct it as a 3D model. This allows engineers to design carpets that fit the floor precisely.

The machine uses a laser beam to scan the car floor, with a camera capturing the surface to reconstruct it as a 3D model. This allows engineers to design carpets that fit the floor precisely.

BUILD.

Industrial 3D Printer

With advances in technology, 3D printing enables the creation of physical models from digital designs. Engineers then assemble these models into the car form for detailed evaluation before moving on to metal mold production.

CNC machining

After the final output of the design process – mold drawings. Using computer data, CNC machines mill metal plates with precision up to hundredths of a millimeter. The plates are then assembled and finished for mass production.

Molding floor mats

- Molded mats are made with injection machines and smart equipment for high precision and fast, large-scale production. We are currently supplies these to VinFast.

- Shaped suction mats use virgin TPE sheets molded by suction. A 200-ton/month extrusion line and robotic cutting ensure speed, accuracy, and safety.

Industrial 3D Printer

CNC machining

Molding floor mats

With advances in technology, 3D printing enables the creation of physical models from digital designs. Engineers then assemble these models into the car form for detailed evaluation before moving on to metal mold production.

After the final output of the design process – mold drawings. Using computer data, CNC machines mill metal plates with precision up to hundredths of a millimeter. The plates are then assembled and finished for mass production.

- Molded mats are made with injection machines and smart equipment for high precision and fast, large-scale production. We are currently supplies these to VinFast.

- Shaped suction mats use virgin TPE sheets molded by suction. A 200-ton/month extrusion line and robotic cutting ensure speed, accuracy, and safety.

DELIVER.

Reliable Delivery of High-Quality Auto Accessories

Zingmove ensures strict quality control and efficient production to deliver durable, perfectly fitting TPE mats and accessories. With large-scale capacity and competitive pricing, Zingmove meets nationwide demand for molded and vacuum-formed mats, plus other auto accessories like 3D walls and door sill borders protect against spills and scratches, with a lifespan of over 10 years.

Reliable Delivery of

High-Quality Auto Accessories

Zingmove ensures strict quality control and efficient production to deliver durable, perfectly fitting TPE mats and accessories. With large-scale capacity and competitive pricing, Zingmove meets nationwide demand for molded and vacuum-formed mats, plus other auto accessories like 3D walls and door sill borders protect against spills and scratches, with a lifespan of over 10 years.